Proud to be Italian

Besides pizza there is much more!

The pride of being Italian comes from a history rich in technology, culture, creativity, art and invention. Italians are recognized all over the world for the quality of their products; for the aesthetic Good Taste which translates into prestigious Design and High Fashion garments but also for the culinary one, with Wines and Chefs at the top of all the rankings. Italians are famous for their Technical / Scientific Excellence ranging from automobiles to the aerospace sector up to sensational discoveries in various fields.

We do not want to say that we are Leonardo da Vinci or Raffaello Sanzio, we are certainly not men like Rubbia and we are not even Bottura or Aulenti.

We certainly have some of this in our DNA and it can be found in everything we do. Even when we looks crazy, even when we let ourselves be recognized for the passion we put into what we do and for the involvement that drives us and makes us Italians! And, anyway, our pizza is the best in the world.

A few words About Us

Our company was founded in 1966, the first independent die shop in Southern Europe. We’ve been the first ones to use integrated CAD-CAM systems and CNC machinery, at times when aluminium extrusion dies were still handmade. In 1987 we turn out to be part of Alcoa, and in 2004 we become a private enterprise with the name Almax Mori srl. Today we’re internationally recognised as a vanguard plant, thanks to our R&D department and to a long lasting partnership with universities and International research centres.

Nice to Meet You

Tommaso Pinter

graduated in Industrial Engineering from Università di Trento nearly two decades ago and later studied metal forming processes at Bologna University. He is currently the CCO of Almax Mori

Riccardo Pinter

graduated in Economics from Università di Trento and he is currently managing Almax Mori back office

Valter Lutteri

has 30 years of experience in die design and today is the chief of Almax Mori technical office

Paolo Caporali

is an expert of mechatronics in charge of computer technology and post processing

Piermario Locatelli and Claudio Pinter

founded Almax Mori in 1987 and today are considered two anchor men of the die making industry

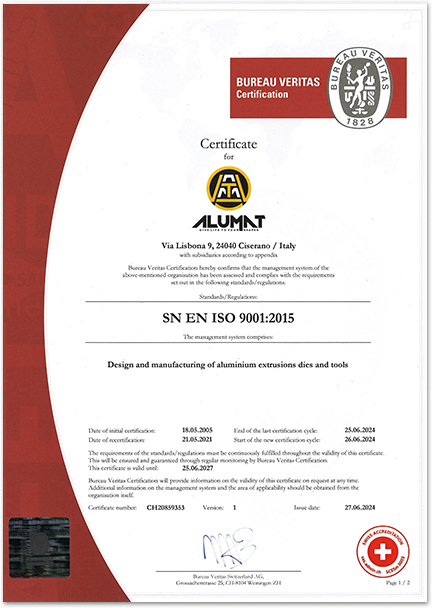

You DESERVE Quality!

The quality that matters the most is the one perceived by our customers.

In Mori people like to say «we do it as we should, no less».

For Almax “Quality” is a mix of design, numerical analysis, manufacturing and quality checks during all production stages.

Design, simulation and manufacturing are compatible and interconnected. Quality is first done by the engineer that chooses the right concept for a specific profile and alloy. Second comes the extrusion simulation that validates the concept or forces designers to revise the constructive drawing of the die. Then is time to manufacture the die to be exactly same as the one validated using FEA.

Last, but not least, an automatic laser scanning system certifies that the physical die has been manufactured true to the model in all of his sections. Thanks to this approach Almax Mori have been reaching outstanding repeatability levels for back-up dies and is the ideal partner for automotive platforms.

Almax Mori claims to be the only die vendor on the market capable to apply FEA to the design to any die produced (including backup copies), to mill all of the mandrel using 5 axis machines and finally certifying that tool produced is true to the 3D model.

That is making the difference.